- Tel: +44 (0) 208 305 0792

- FAX: +44 (0) 208 858 0101

- info@stoneleigh-eng.com

See below a selection of the valve products we supply and service.

Please click HERE for general information on Valves

If you have any questions or require additional information please do not hesitate to contact us. One of our experienced team will be happy to assist.

Resilient, Tricentric, Triple Offset Torque Seated, High Performance & more

Widely used throughout the Petroleum, Refinery and general industrial sectors

Round or Rectangular gate or wedge type, rising or nonrising stem & more

Various types are available in order to satisfy specific applications..

VALVES

General Information On Valves

The valve is a device that controls and regulates the flow of gases, liquids, fluidized solids or slurries by opening, closing, or partially obstructing various passageways. Although valves are technically pipe fittings, they are also referred to in a different category. In an open valve, fluid flows in a direction from high pressure to low pressure.

Valves are used in different contexts. For example: industrial, government, military, petroleum, commercial, residential and transport.

Industries in which the most valves are used are petrleom (oil and gas), power generation, mining, water reticulation, papermills, refineries, sewerage and chemical manufacturing.

Common valves are plumbing valves. Taps for hot and cold tap water are the most visable types of valves. Other types used on a daily basis include gas control valves on cookers, small valves fitted to washing machines and dishwashers, and safety devices fitted to hot water systems.

Valves may be operated manually. Hand wheel, lever or pedal. Valves may also be automatic, driven by changes in pressure, temperature, or flow. The changes may act upon a diaphragm or a piston which in turn activates the valve, examples of this type of valve found commonly are safety valves fitted to hot water systems or boilers.

More complex control type systems using valves requiring automatic control based on an external input (i.e., regulating flow through a pipe to a changing set point) require an actuator. An actuator will stroke the valve depending on its input and set-up, allowing the valve to be positioned accurately, and allowing control over a variety of requirements.

Types

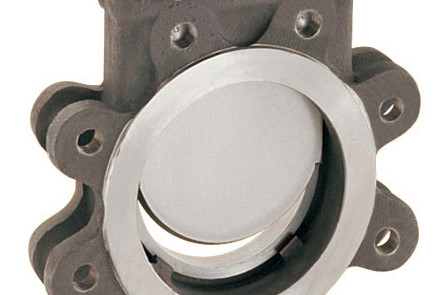

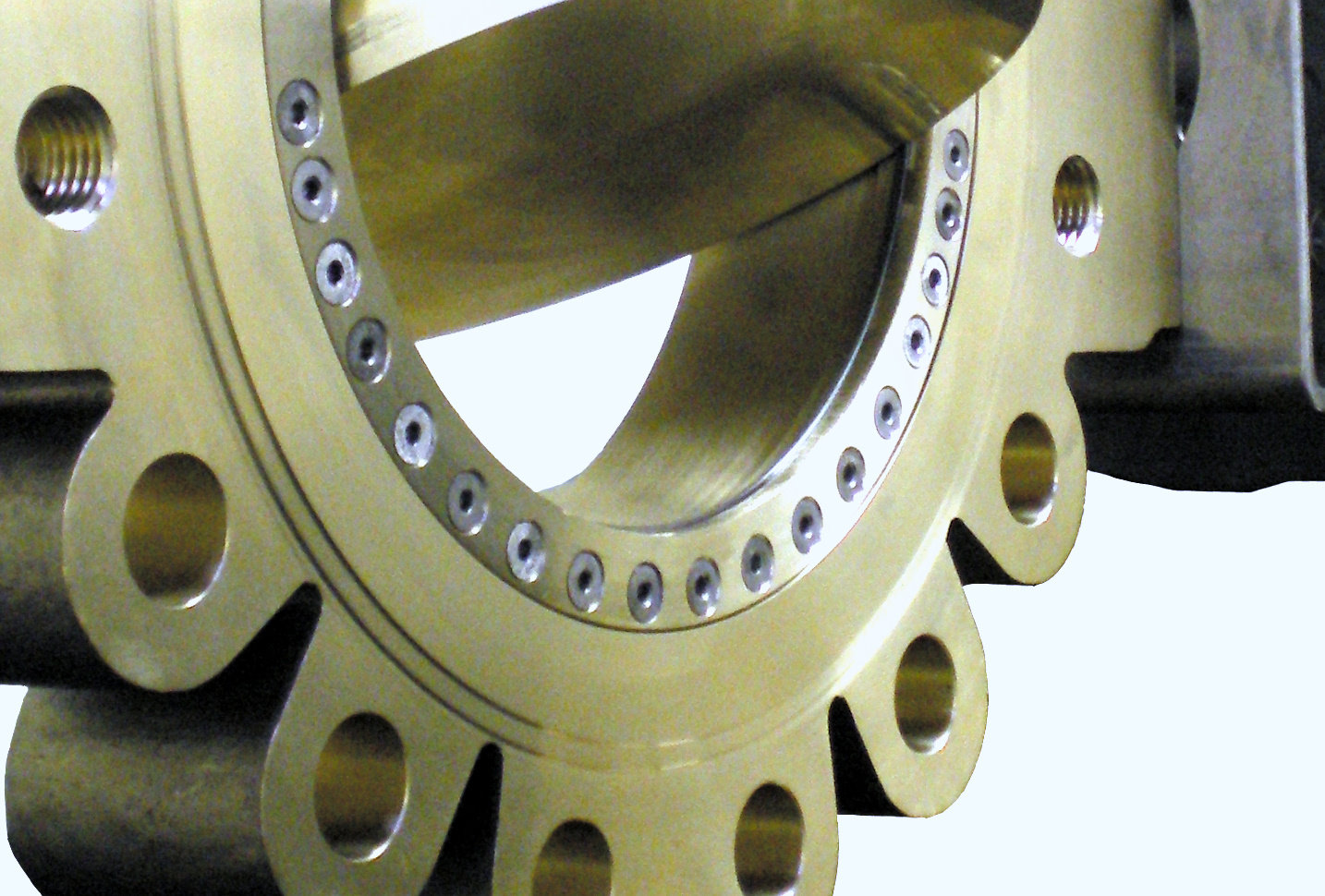

The inside of an extremely large butterfly valveValves are quite diverse and may be classified into a number of basic types. Valves may also be classified by how they are actuated:

- Hydraulic

- Manual

- Pneumatic

- Motor

- Solenoid

Basic types Valves can be categorized into the following:

- Duplex ball valve for on/off control without pressure drop, and ideal for quick shut-off since a 90deg turn offers complete shut-off angle, compared to multiple turns required on most manual valves.

- Butterfly valves, for flow regulation in large pipe diameters.

- Check valve or non-return valves, allows the fluid to pass in one direction only.

- Choke valves, a valve that raises or lowers a solid cylinder which is placed around or inside another cylinder which has holes or slots. Used for high pressure drops found in oil and gas wellheads.

- Hastelloy check valve Diaphragm valve, some are sanitary predominantly used in the pharmaceutical and foodstuff industry.

- Ceramic Disc valves, used mainly in high duty cycle applications or on abrasive fluids. Ceramic disc can also provide Class IV seat leakage

- Gate valves, mainly for on/off control, with low pressure drop.

- Stainless steel gate valves, Globe valves, good for regulating flow. Knife valve, for slurries or powders on/off control. Needle valve for accurate flow control.

- Piston valves, for regulating fluids that carry solids in suspension. Pinch valve, for slurry flow regulation.

- Plug valve, slim valve for on/off control but with some pressure drop.

- Spool valves, for hydraulic control Thermal expansion valve, used in refrigeration and air conditioning systems.

- Poppet valves

Specific valve types:

- 4-stroke cycle engine valve: an application of piston valve

- Aspin: a cone-shaped metal part fitted to the cylinder head of an engine

- Ball cock: often used as a water level controller (cistern)

- Bibcock: provides a connection to a flexible hosepipe

- Blast: prevents rapid overpressures in a fallout shelter or a bunker Cock: colloquial term for a small valve or a stopcock

- Demand: on a diving regulator

- Double beat or Double check valve

- Duckbill or Flipper valve

- Flow control: an application which maintains a constant flow rate through the valves

- Heimlich: a specific one-way valve used on the end of chest drain tubes to treat a pneumothorax

- Foot: a check valve on the foot of a suction line to prevent backflow

- Four-way: was used to control the flow of steam to the cylinder of early double-acting steam engines

- Freeze seal/Freeze plug: in which freezing and melting the fluid creates and removes a plug of frozen material acting as the valve

- Gas pressure regulator regulates the flow and pressure of a gas Heart valve: regulates blood flow through the heart in many organisms

- Leaf: one-way valve consisting of a diagonal obstruction with an opening covered by a hinged flap

- Pilot: regulate flow or pressure to other valves

- Poppet and sleeve valves: commonly used in piston engines to regulate the fuel mixture intake and exhaust

- Pressure regulator or pressure reducing valve (PRV): reduces pressure to a preset level downstream of the valve

- Pressure sustaining valve, or back-pressure regulator: maintains pressure at a preset level upstream of the valve

- Presta and Schrader valves are used to hold the air in bicycle tires

- Reed: consists of two or more flexible materials pressed together along much of their length, but with the influx area open to allow one-way flow, much like a heart valve

- Regulator: used in SCUBA diving equipment and in gas cooking equipment to reduce the high pressure gas supply to a lower working pressure

- Rocker valve, Rotary valves and piston valves: parts of brass instruments used to change their pitch

- Rupture disc: a one time use replaceable valve for rapid pressure relief, used to protect piping systems from excessive pressure or vacuum; more reliable than a safety valve

- Saddle valve: where allowed, is used to tap a pipe for a low-flow need

- Safety valve or relief valve: operates automatically at a set differential pressure to correct a potentially dangerous situation, typically over-pressure

- Schrader valve: used to hold the air inside automobile tires Solenoid valve: an electrically controlled hydraulic or pneumatic valve

- Stopcock: restricts or isolates flow through a pipe Swirl valve: A specially designed

- Joule-Thompson pressure reduction/expansion valve imparting a centrifugal force upon the discharge stream for improving gas-liquid phase separation

- Tap (British English), faucet (American English): the common name for a valve used in homes to regulate water flow Thermal expansion valve, used in air conditioning and refrigeration systems.

- Thermostatic Mixing Valve Thermostatic Radiator Valve Trap primer: sometimes include other types of valves, or are valves themselves Vacuum breaker valve: prevents the back-siphonage of contaminated water into pressurized drinkable water supplies